The heat treatment department was organised together with machining and production departments, in order to complete the entire manufacturing process for moulds and production machines for concrete decorative products. Investments in modern, state-of-the-art equipment and machinery was the prerequisite for manufacture of high-performance machines and plants. Correct heat treatment ensures long life of our machines and moulds for production of concrete paving blocks and decorative products.

The quality of our services is also appreciated by other companies. TECHMATIK co-operates with many companies in Poland and abroad. Among our regular customers there are FABRYKA ŁOŻYSK TOCZNYCH in Kraśnik; BEFARED in Bielsko-Biała (manufacturer of gear-motors); BRUKPOL with its seat in Bukowiec near Łódź (precision industry); INTERNATIONAL TOBACCO MACHINERY in Radom; PMP Poland in Jelenia Góra (production for papermaking industry); BRAT-MET in Radom (manufacturer of fasteners); BOMBARDIER; HELLER; and COLUMBIA.

SERVICES

Our Company offers the following services from the heat treatment sector:

ITEMS | PROCESS | FURNACE TYPE | DIMENSIONS OF FURNACE HEATING CHAMBER [length x width x height] | MAXIMUM WEIGHT OF TREATED ELEMENT |

1. | Hardening | AFS-34 | 2250 x 1400 x 1000 mm | 900 kg |

2. | Normalising | AFS-34 | 2250 x 1400 x 1000 mm | 1200 kg |

3. | Carbonisation | AFS-34 | 2250 x 1400 x 1000 mm | 1200 kg |

4. | Cyanide hardening | AFS-34 | 2250 x 1400 x 1000 mm | 900 kg |

5. | Annealing | BREAW-34 | 2250 x 1400 x 1000 mm | 1500 kg |

6. | Nitriding | RM24/12/10/RVE | 2250 x 1400 x 1000 mm | 1500 kg |

HARDENING SHOP EQUIPMENT

HARDENING FURNACES AND LOADING/UNLOADING TABLE

The heat treatment processes are carried out in chamber furnaces with endothermic atmosphere with adjustable carbon potential; the furnaces are rated among the most modern pieces of equipment in our region of Europe. We also run heat treatment processes in the nitriding furnaces with vacuum evacuation. Processes like hardening, carbonisation, cyanide hardening and annealing are carried out in the process line based on chamber furnaces with built-in SEALED QUENCH quenching tank type CASE MASTER AFS-34. The line also includes auxiliary devices such as washing machine, furnace for high-temperature tempering, endothermic atmosphere generators and loading/unloading tables.

NITRIDING FURNACE AND WASHING MACHINE

NITRIDING FURNACE AND WASHING MACHINE

The hardening shop is also equipped with the process line for ammonia nitriding, consisting of the furnace for ammonia nitriding with vacuum evacuation and the washing machine for cleaning the parts prior to the process.

The effects of heat treatment are evaluated in metallographic laboratory where, using equipment such as devices for preparing the metallographic specimens, micro-hardness tester and metallographic microscope, it is possible to evaluate the structure and thickness of layers after thermochemical treatment and hardness distribution. The results of measurements for individual processes are filed, and specimens with numbers of production orders are stored for one year.

The heat treatment process is controlled by a computer with suitable software installed. Due to the endothermic atmosphere and appropriate control of the process we can guarantee the best quality of parts undergoing heat treatment, a very good repeatability of processes, minimization of deformations during the hardening process and the absence of soft skins and oxidized areas.

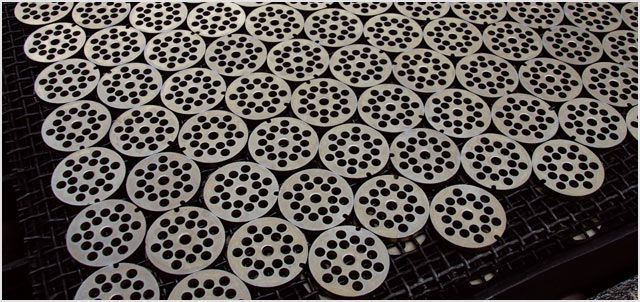

ELEMENTS PREPARED FOR HEAT TREATMENT

CONTACT

Ireneusz Kowalski

Manager, Heat Treatment Department

mobile +48 / 668 122 208

phone / faks +48 48 / 369 08 94

e-mail ikowalski@techmatik.pl