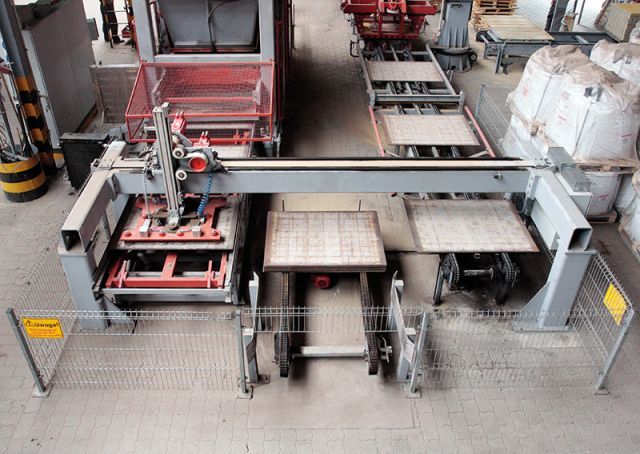

The task of the robot is to collect finished concrete products from the v-belt cs conveyor, transfer it to, and stack on commercial pallets.

While developing this machine, very sophisticated engineering solutions were applied, until recently used in high-precision industrial machines only. Robomatik has compact structure, works quietly, and with high dynamic of movements. At the same time, high positioning accuracy of transported products has been obtained and product damages during packaging have been virtually eliminated.

Application of counterbalance in the robot structure results in an increased energy saving, despite fast operation and significant load.

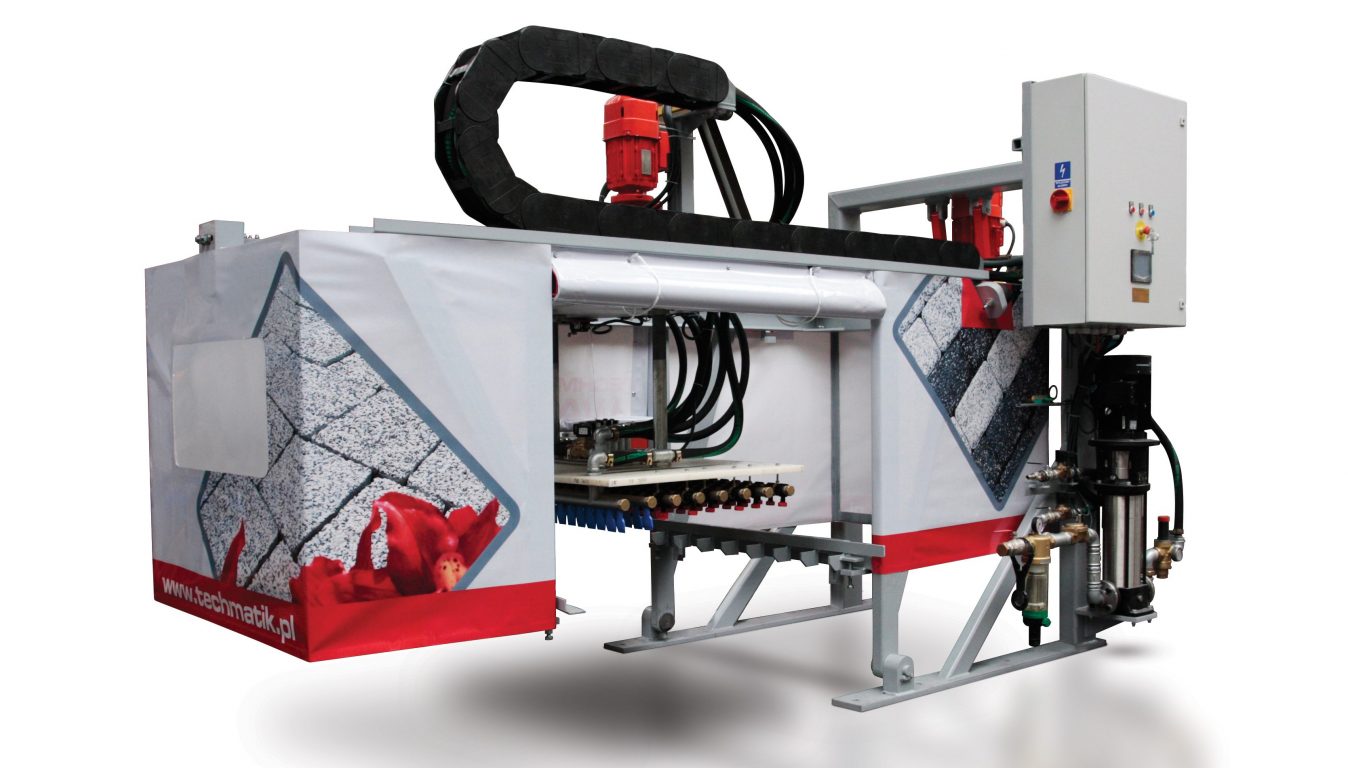

The WASHMATIK wash-out machine is part of the production plant for manufacturing concrete pavers and decorative products. Thanks to its enhanced concrete pavers and paving tiles can be obtained. The machine, through water and air nozzles, washes out the upper layer of the product in order to expose decorative aggregate (granite, basalt, marble and the like). Such enhanced products are used for arranging elegant paths, alleys, and squares, thus enhancing their aesthetic and functional values.

ADVANTAGES OF THE WASHMATIK WASH-OUT MACHINE

- High speed of washing and high performance,

- Uniform flushing on the entire board surface (perfect quality),

- Steplessly adjustable movement of the nozzle unit,

- Intuitive navigation interface,

- Independent on/off parameter change in every nozzle section (economical water usage),

- Steplessly adjustable product washing depth,

- Easy adaptation to existing production plants,

- Operational reliability,

- Simple construction enabling easy operation and maintenance.

The automatic wrapping machine is fitted with a device for wrapping with a strap with manufacturer’s logo. The wrapping machine enables simultaneous wrapping with a stretch film and a tape (without adhesives) with manufacturer’s logo. The column design of the wrapping machine, due to the application of proven design solutions such as counterweight and linear bearings has a compact and stable structure. Due to the application of an innovative wrapping system with a strap with manufacturer’s logo, this wrapping machine is the first wrapper of this type on the market.

The device is intended for feeding commercial pallets to the station of the ROBOMATIC packaging robot which performs the packaging cycle of finished products. It is equipped only with a pneumatic drive run by FESTO actuators. The operation of both devices is synchronized and carried out automatically. The feeder is equipped with:

• storage for 30 pallets that may be delivered by a forklift

• conveyor that smoothly transports the pallets.

ADVANTAGES OF THE FEEDER

• increased work safety by automatic delivery of commercial pallets to the production plant

• simplicity of design

• compact structure that limits the dimensions of the production plant

• innovative and reliable structure of the conveyor drive

The device provides storage and smooth circulation of boards in the production plant. Modern motors in the Servo technology applied in the structure, along with belt drives and linear bearing systems, ensure quiet operation, high positioning accuracy of the board conveyor unit, and short operation cycles.

The reject tipper is intended for removing products qualified as rejects from the board, by rotating the board by an angle that allows the products to slip. The device can be also used to remove excess water from products after the flushing process.

The reject tipper is located in the so-called wet side of the production plant. The device has sideboards that are automatically lowered to the position enabling controlled emptying of the board. The device has simple structure and is reliable in operation. The belt drive transmission as well as structural solutions of movable parts reduce noise during the operation.

ADVANTAGES OF THE REJECT PRODUCTS TIPPER

• Simple structure that provides reliable and quiet operation,

• Dual function (removal of rejects and pre-drying – removal of excess water) shortening the production cycle,

• Increased safety by automatic removal of rejects from the production plant.

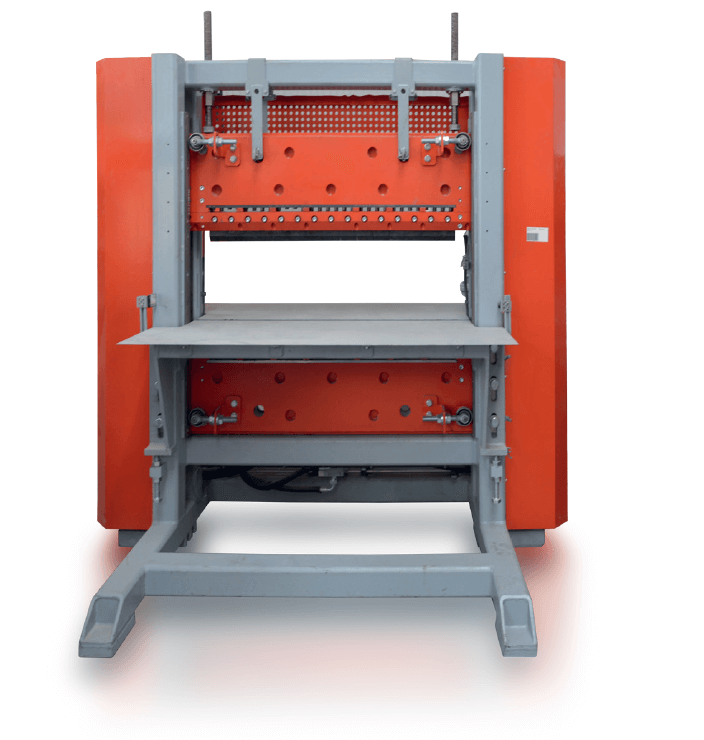

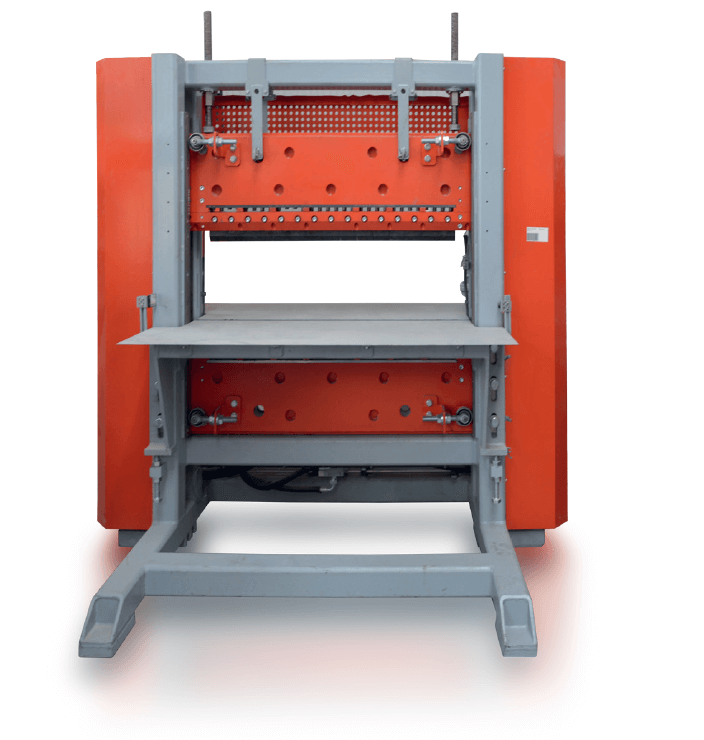

The splitters represent a new product series of machines for splitting concrete products. The machine body, working elements (hydraulic actuators incl.) have been developed and manufactured by Techmatik. Automatic control components come from reputable manufacturers.

Advantages:

- Precise splitting of large packages

- Possibility of splitting natural stone

- Adjustable working table

Ergonomics and versatility, due to:

- Bar setting structure, where the system of two actuators of 165m stroke and two pull actuators of 400 mm stroke is connected with splitting jaws, which prevents load transfer to the arm of the splitter. This system also provides the ability to adjust the splitting jaws to a stone with an irregular shape. Thanks to the height-adjustable table the splitter may be fitted into the existing conveyor flight.

- A hydraulic station with the nominal working pressure of 200 bar is driven by an 7.5 kW electric motor, equipped with an oil cooler with 0.12 kW fan .

Application:

The machine is intended for splitting entire packages of stones and enables also splitting irregularly shaped natural stones.

Splitters – proven solutions:

- Side actuators are equipped with linear guides

- Adjustable limit switches enabling stepless adjustment of knife’s working stroke depending on the size of the split products

- High safety of operator’s work thanks to the application of synchronized controls, safety switches, and steplessly adjustable workspace shields.

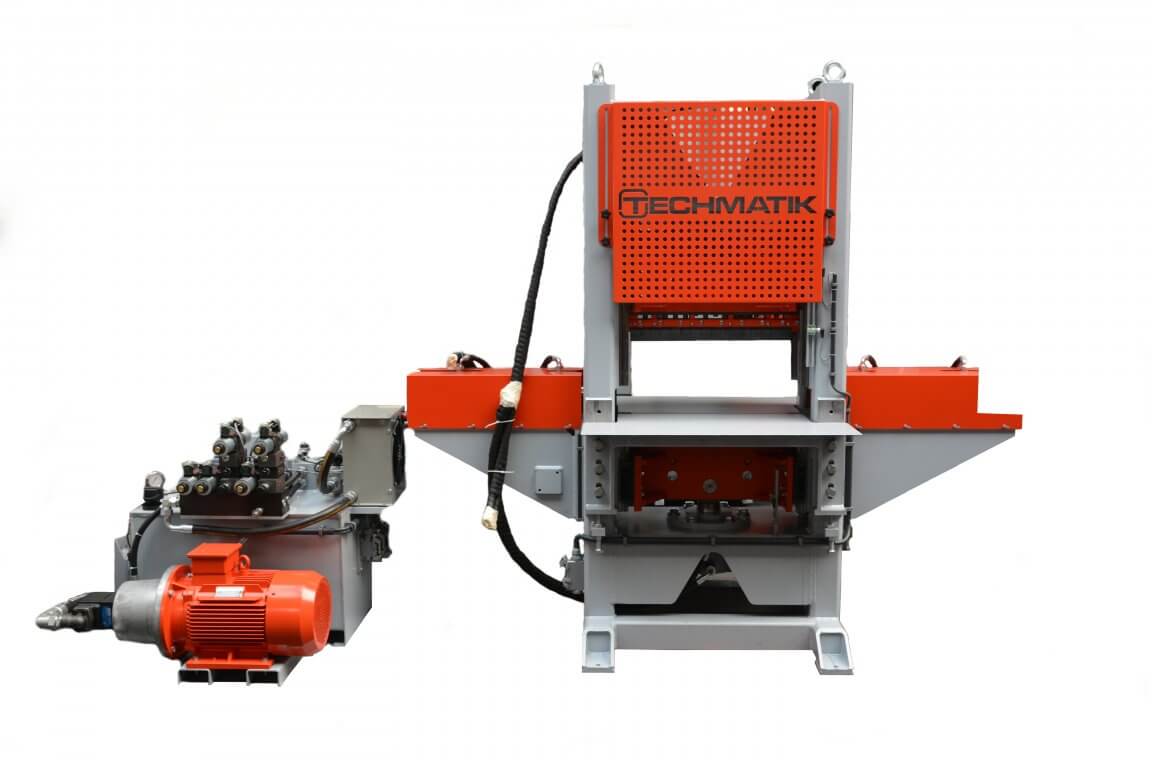

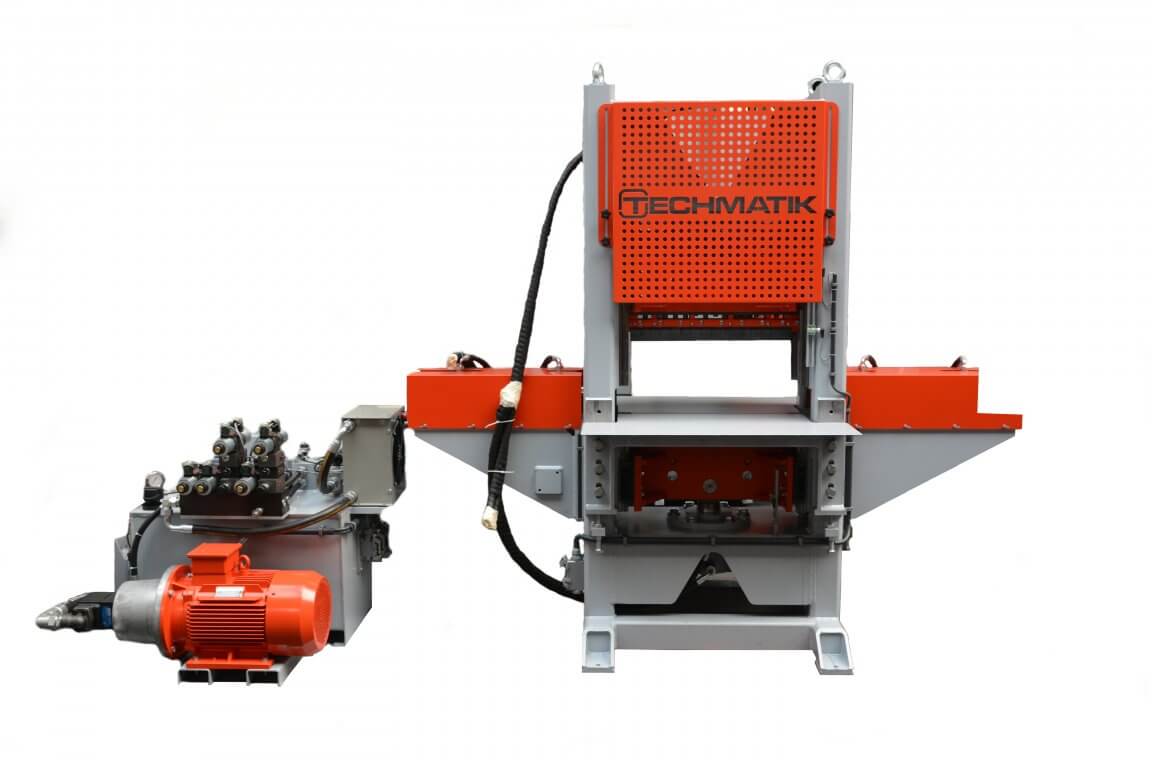

The splitters represent a new product series of machines for splitting concrete products. The machine body, working elements (hydraulic actuators incl.) have been developed and manufactured by Techmatik. Automatic control components come from reputable manufacturers.

Advantages:

- Blade structure that adapts to the surfaces of the split product

- Quick extendable working space of the table through quick installable additional boards

- Greater splitting force (the contact force of the basic actuators increased to 615 kN, side actuators increased to 220 kN)

- New hydraulic station with improved performance

- New stabilization system of basic knifes

- More rigid design of the supporting frame and table.

Ergonomics and versatility, due to:

Bar setting structure, where the system of two actuators of 165m stroke and two pull actuators of 400 mm stroke is connected with splitting jaws, which prevents load transfer to the arm of the splitter. This system also provides the ability to adjust the splitting jaws to a stone with an irregular shape. Thanks to the height-adjustable table the splitter may be fitted into the existing conveyor flight.

A hydraulic station with the nominal working pressure of 200 bar is driven by an 7.5 kW electric motor, equipped with an oil cooler with 0.12 kW fan.

Application:

The machine is intended for splitting entire packages of stones and enables also splitting irregularly shaped natural stones.

Splitters – proven solutions:

- Side actuators are equipped with linear guides

- Adjustable limit switches enabling stepless adjustment of knife’s working stroke depending on the size of the split products

- High safety of operator’s work thanks to the application of synchronized controls, safety switches, and steplessly adjustable workspace shields.

ADVANTAGES OF THE AGGREGATE DOSING LINE

- Dosing accuracy (road safety)

- Collision-free loading (no damages to a trailer by a loader)

- Cost reduction of loader maintenance and operation

- Control system providing continuous production of aggregates and their loading

- Self-service by the truck driver

- Safety while loading thanks to the light signaling system and ultrasonic sensors

- Fully automated aggregate production system

- Wide scope of adaptation

- Possibility of dosing different kinds of raw materials (aggregate, coal, and the like)

- Reliability of operation based on electronic components from renowned manufacturers

Apart from systems cooperating with machines for the production of dry-cast products, our company also provides concrete batching plants for the production of ready-mixed concrete. Continue reading “Concrete batching plants” →

ADVANTAGES OF THE MIXERS

• Short mixing cycle through the initial water dosing

• Accurate mixing of concrete mix due to optimum number of mixing blades

• Compact design and reliable drives delivered by the SEW company

• Simple operation and easy maintenance

• Quiet operation

• Integrated hydraulic station

STANDARD VERSION

• 8 years warranty period for the mixer

• Special steel lining of HARDOX 500, 700 type

• One discharge flap opened downwards, hydraulically controlled

• Emergency opening by a manual pump in case of power failure

• Safety system for cleaning the mixer – the door is blocked during mixer operation

• Mixing unit equipped with polyurethane blades and scrapers

• AIR BAG venting system

ADDITIONAL OPTIONS

• Washing nozzles system with initial water dosing

• Moisture content measuring probe

• Additional hydraulically opened discharge flap

• Discharge flap opened horizontally, hydraulically or pneumatically controlled

• Inspection glass

• Wirbler

The Tumbler is designed for mechanical surface treatment of concrete pavers, and its task is to provide the pavers antiqued look, achieving a vintage pavement effect.

The main element of the machine is the rotary drum, where the concrete pavers are loaded. During the rumbling process the product edges break and marks imitating long-term wear appear.